By Portia Williams

PORTSMOUTH — Since 1996, The Portsmouth Brewing Company has been considered by many people a favorite hometown meeting spot for beer, tantalizing food and plenty of comfort.

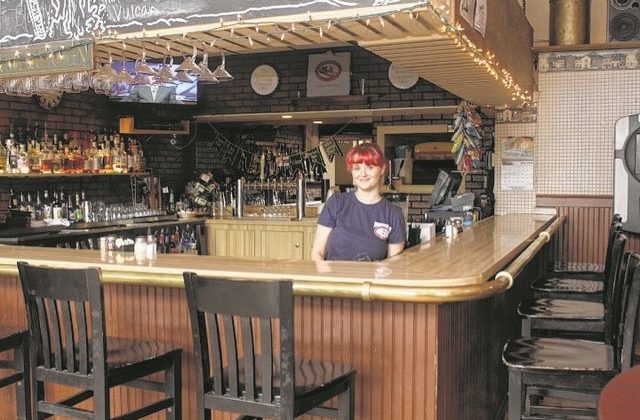

Housed in beautiful brick masonry in downtown Portsmouth, PBC is also home to the Brew Pub, a quaint restaurant attracting frequent visitors for both lunch and dinner.

A work crew from local contractor BB & E was recently enjoying lunch at the Brew Pub. One worker was especially enthusiastic about its fare.

“The end of Second Street is the best with the Brew Pub,” said Tony Eichenlaub, of BB & E. “If I could eat here five days a week I would.”

Tyler Mault, head of operations for PBC, said he has been a part of the business since birth when his grandfather, Steve Mault, opened it in 1996.

Members of the Mault family are no stranger to business. They are also the owners and operators of another hometown favorite, a restaurant called The Ribber.

“My grandfather, Steven, and grandmother, Cornelia Mault, started The Ribber in 1978, and then my grandfather opened up the Portsmouth Brewery in 1996. So, my father, aunt and uncle own and operate The Ribber,” Mault said. “My grandfather comes back from time to time, but I basically oversee things here.”

The PBC was reinvigorated in 2000 because of what Mault called the “craft beer craze” and the community wanting to support local businesses.

PBC’s mission is to expand throughout the tristate area of Ohio, Kentucky and West Virginia. Mault said he believed that’s what the brewery set out to do when it opened in 1843, according to historical documents he’s read.

He said, “Right now, we are in Ohio, from the southern half of the state, and then we are in the entire state of West Virginia, and we are about ready to get back into Kentucky. We would love to get the community more involved with the brewery as we continue to grow.”

The brewery typically has five to six employees, depending upon the time of year.

“Our brewmaster’s name is Tony Thompson, and he has been with us from the beginning, since 1997. Then we have Brian Collins, who is basically a brewmaster’s apprentice, helping the brewmaster out with anything that he needs,” Mault said. “Then we have a warehouse manager … Adam Chaney.”

The Mault family incorporates certain philosophies that have been conducive to its success in business.

“Values and loyalty to employees, I would say, have gotten us this far,” Mault said. “If you show that you are a hard worker, and show that you are about the cause of sustaining a successful business, if you give us those things, we transport you the best that we can.”

Tyler Mault said brewmaster Tony Thompson first does what is called “mashing.” He loads in a hopper upstairs in the attic anywhere between 400 to 700 pounds of grain. The product is then dropped into a mash tun. Then, he will run 164-degree water in with the grain.

“So, what he is doing when he does this is milling the grain, and what the hot water is doing is soaking all of the starches and sugars out of the water,” Mault said.

Sugar water is formulating at this point in the process, according to Mault.

The hot water is allowed to set in the grain for about one hour. It is then drained into what they call “the boil,” or kettle, which takes about one hour, as well.

“So, with the sugar water, all starches and sugars are being drained into the kettle, and we’ll add water to it. So, total, we will have about 10 barrels of beer boiling at once, so we make 10-barrel batches,” Mault said.

After the sugar water is collected into the boiled kettle, hops are added, which basically add bitterness to the beer, depending upon what style of beer is being brewed.

Alcohol is produced when the hops are added to the ingredients.

“After all the ingredients (are) added and the beer has brewed for an hour, and the hops are added, we will just drain into one of the fermenters, and we will pitch the yeast which is what produces the alcohol,” Mault said. “So, after that is done, depending on whether it’s an ale or a lager, an ale takes two weeks to make, and lager takes four weeks to make.”

Bottling, packaging and kegging take the PBC approximately three to four days to complete.

Mault said people in the Portsmouth area like the Portsmouth Pilsner and the Red Bird Ale. He said those are the two beers they started brewing in 1997, or when “I was about 6 years old.”

THE PORTSMOUTH BREWING COMPANY

Address: 224 Second St., Portsmouth, OH 45662

Phone: 740-354-6106

Email: [email protected]

Website: portsmouthohbrewing.com

Facebook: facebook.com/PortsBrewCo

Twitter: twitter.com/ThePortBrewCo

Hours: 11 a.m. to 10 p.m. Monday through Thursday; 11 a.m. to 11 p.m. Friday and Saturday; noon-10 p.m. Sunday

ID, 'source', true); $sourcelink = get_post_meta($post->ID, 'sourcelink', true); $sourcestring = '' . __('SOURCE','gabfire') . ''; if ($sourcelink != '') { echo "

$sourcestring: $source

"; } elseif ($source != '') { echo "$sourcestring: $source

"; } // Display pagination $args = array( 'before' => '' . __('Pages:','gabfire'), 'after' => '

', 'link_before' => '', 'link_after' => '', 'next_or_number' => 'number', 'nextpagelink' => __('Next page', 'gabfire'), 'previouspagelink' => __('Previous page', 'gabfire'), 'pagelink' => '%', 'echo' => 1 ); wp_link_pages($args); // Display edit post link to site admin edit_post_link(__('Edit','gabfire'),'','

'); // Post Widget gab_dynamic_sidebar('PostWidget'); ?>